Big little solutions

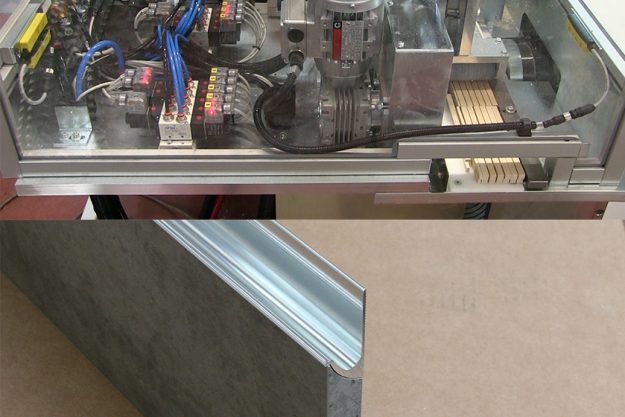

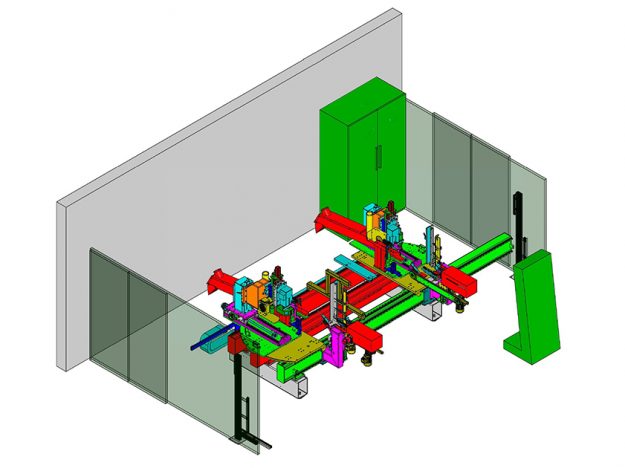

If they can stay in a single truck they can fit a single post too! They’re two special solutions which allow two different customers to evolve their production process both effectively and efficiently. Let’s start from this one: cross cutting and multi rip saw to get wooden sticks from bars. They are used in northern…